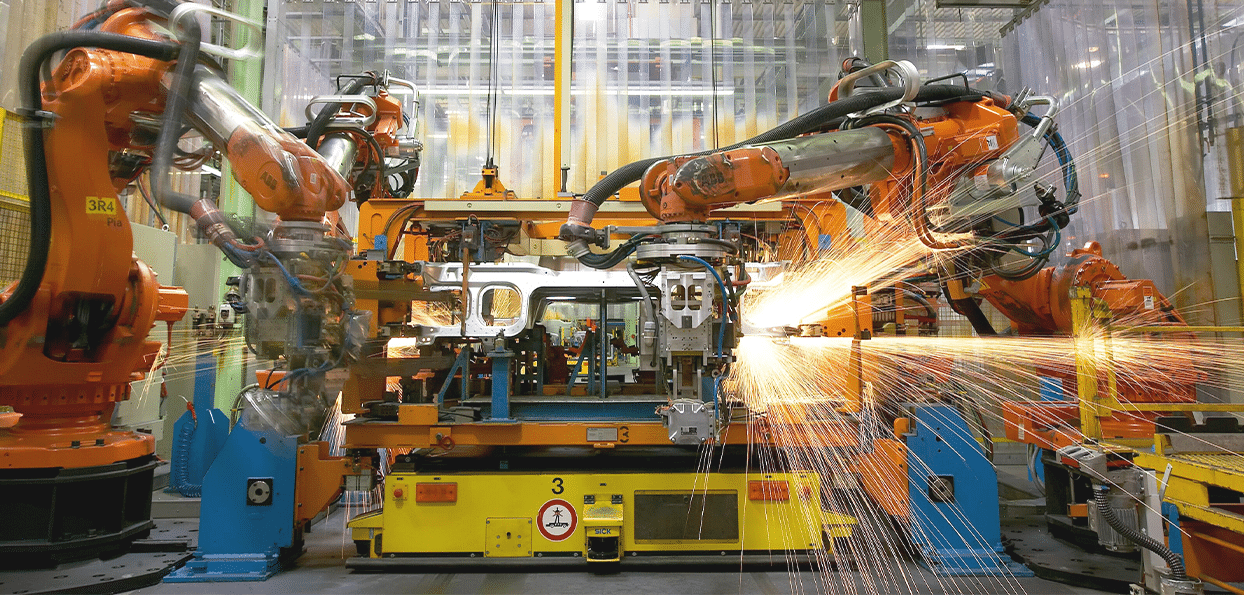

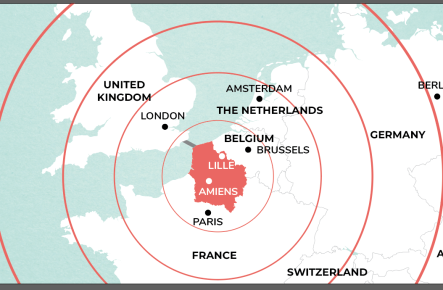

Two years after its creation as a trial project and having raised 10 million euros in funding, Battri has reached a crucial milestone with the launch of its first industrial site in Saint-Laurent-Blangy. This 161,459 sq. ft. site, which is dedicated to the pre-processing of lithium-ion batteries, marks the company’s operational launch.

This process includes collecting, diagnosing, dismantling, crushing, and separating materials to extract the “black mass,” which is rich in nickel, cobalt, graphite, and lithium. This strategic material is then sold to specialized partners for refining and reuse in the manufacture of new batteries. The other components—aluminum, copper, iron, polymers—are also recycled.

Battri estimates its initial capacity at 15,000 tons per year, with the potential to expand to 35,000 tons by 2026, which means it could recycle 80,000 electric vehicle batteries. This makes it the biggest lithium-ion battery recycling plant in France.

The founders have set themselves a recovery rate of up to 95% of the materials contained in each battery, positioning the company among the best performers in the sector.

This project represents a 20 million euro investment and will allow for the creation of 100 direct jobs, including positions in logistics, laboratory work, management, and specialized operators.

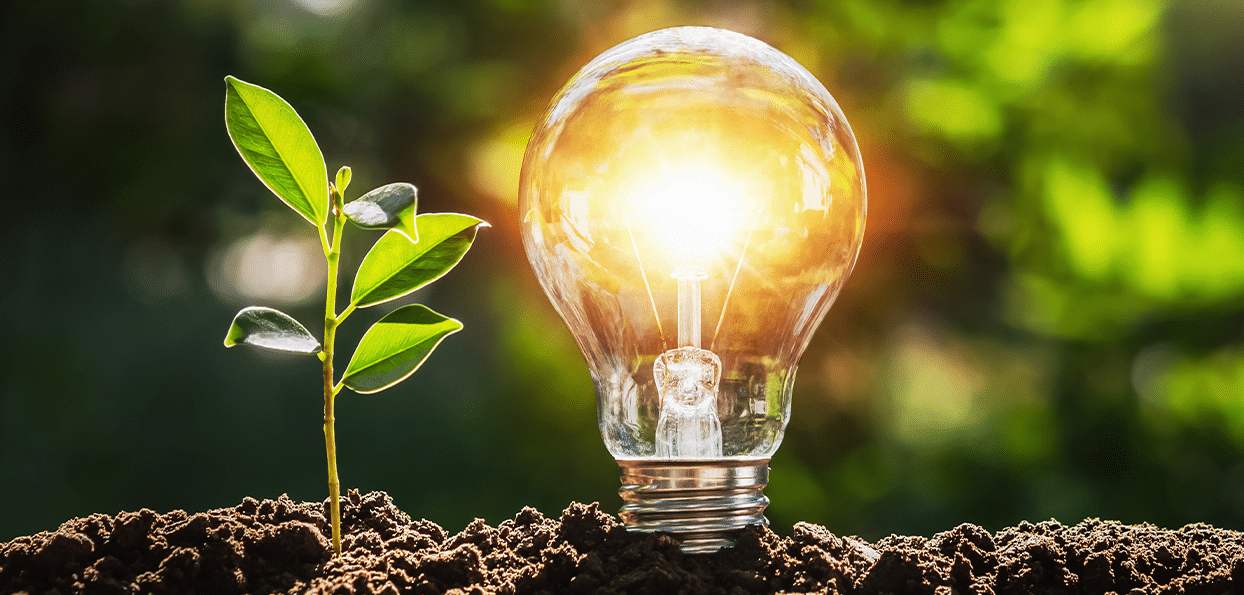

Our goal is simple: to contribute to reducing carbon emissions by recycling lithium-ion batteries safely and efficiently.

Maxime Trèves, Co-founder and CEO of Battri

The site is SEVESO high threshold classified, covers 50% of its energy needs through solar power, cogeneration and heat recovery, and has a full environmental certification.